How Self-Loading Mixer Trucks Reduce Operational Dependencies

Integrated Batching and Mixing Eliminate Ready-Mix Plant Reliance

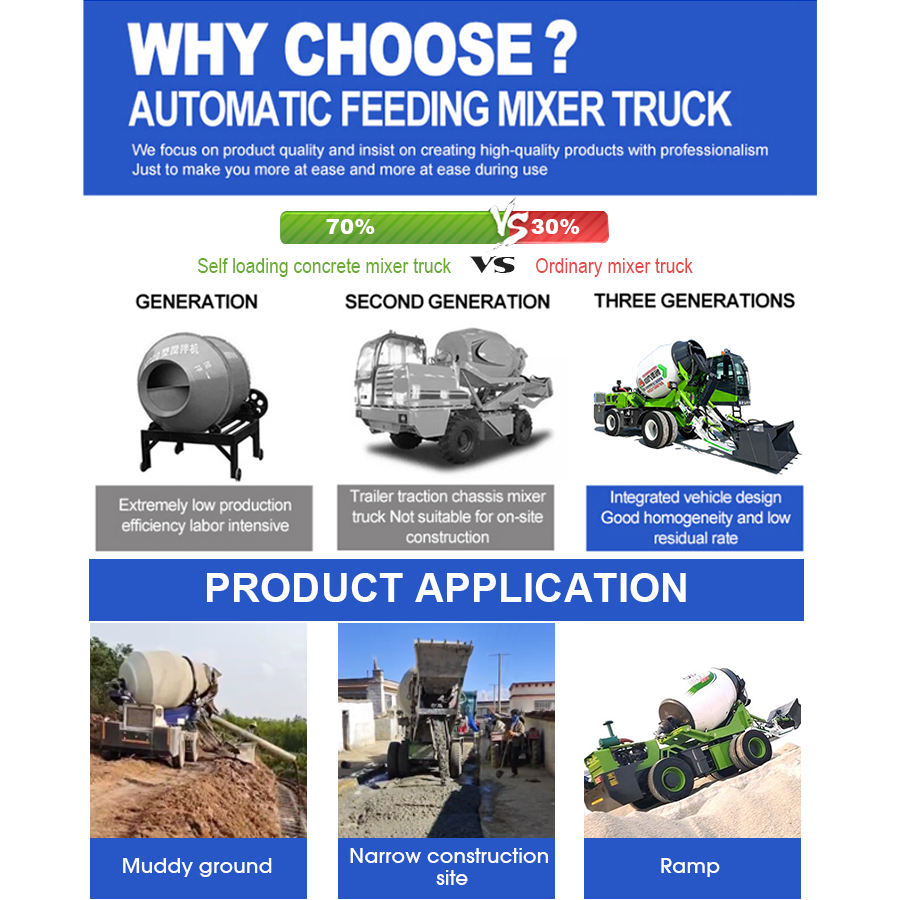

Self loading mixer trucks bring all the concrete production together in one moving machine, so there's no longer a need for those big fixed batching plants around construction sites. When everything from storing materials to measuring and mixing happens right there on board, construction teams save tons of time they would otherwise spend waiting for outside suppliers to deliver stuff. According to research published last year looking at various bridge building operations, workers saved about half their usual setup time when using these mobile mixers instead of traditional methods. The study mentioned something like cutting down on those frustrating 2 to 4 hour waits that happen during plant installation and transferring materials between different locations.

Real-Time Concrete Adjustments Without Supplier Coordination

With onboard automation now available, workers can tweak mix designs right as they pour concrete, which means they don't have to wait around for those outside ready-mix trucks anymore. The system includes water sensors along with volumetric dosing equipment that lets them make adjustments every 8 minutes or so. According to SQMG's 2022 report, this setup cuts down on wasted materials by roughly 18 percent when working on tall buildings. And let's not forget about time savings either. Contractors typically save about seven and a half hours each day that used to get eaten up waiting for new batches because someone messed up the schedule somewhere else.

Autonomy in Remote or Logistically Challenging Job Sites

Self loading mixers with their four wheel drive systems and bodies that can squeeze through spaces just over three meters wide actually reach places regular equipment simply cannot get to. Mountain communities have seen foundation projects wrap up around twelve days quicker compared to old fashioned plant based approaches because there's no waiting for deliveries anymore according to recent infrastructure studies from last year. Another big plus comes from how these machines only need one person to operate them instead of whole crews needed for traditional setups involving multiple pieces of machinery, cutting down on staffing requirements by almost three quarters in areas where finding workers is tough going.

Cost and Time Efficiency in Real-World Construction Applications

Self-loading mixer trucks deliver measurable cost and time savings by consolidating equipment and labor functions into one automated system. Projects using these units reduce equipment rental costs by up to 40% by eliminating separate loaders and stationary mixers (Construction Efficiency Report 2023).

Reduced Labor and Equipment Costs Through Functional Integration

The integrated operation reduces labor needs by 2–3 workers per shift compared to traditional workflows. One operator manages loading, mixing, and pouring without additional crew for material handling or mixer oversight, resulting in average daily savings of $640 in labor costs.

Time Savings by Avoiding Ready-Mix Delivery Delays

Projects eliminate 12–18 hours of weekly downtime caused by scheduling conflicts or last-minute design changes with ready-mix suppliers. This preservation of critical path timelines leads to improved on-time completion rates–reported by 78% of contractors using self-loading units (ACI 2022 Project Data).

Long-Term ROI and Faster Project Turnarounds

The $180k–$220k initial investment in self-loading trucks achieves payback in 3–5 years through:

- 45% fewer concrete waste incidents

- 22% faster site-to-site relocation

- Elimination of $15k/month third-party mixing fees

Balancing Upfront Investment with Lifecycle Cost Savings

Although more expensive upfront than standard mixers, lifecycle analysis shows a 27% lower total ownership cost over 8 years due to reduced maintenance and reuse across multiple projects. Modular components extend service life to 12–15 years with proper maintenance, enhancing long-term value.

Precision Automation and Consistent Concrete Quality Control

Onboard Weighing and Automated Mixing for Exact Batching

Today's self loading mixers come equipped with automated batching systems that bring together load cells, moisture sensors, and computer controlled proportioning units. These systems can hit recipe targets pretty accurately, usually within about 1.5 percent according to Transtech research from 2025. Keeping those water cement ratios consistent is really important for making sure structures hold up over time. The onboard weighing systems provide real time feedback that tweaks the mixing process as needed. When there are changes in aggregate moisture levels or when materials arrive late, the system makes automatic adjustments to maintain quality standards throughout production runs.

Guaranteed Concrete Uniformity Across Pouring Cycles

Programmable logic controllers maintain consistent drum speed and rotation during discharge, with slump test variance of ¥3% between first and final pours. Continuous blending prevents aggregate segregation, while temperature-controlled compartments support optimal curing conditions–essential for large, uninterrupted placements.

Minimized Material Waste Through On-Demand Mixing

Just-in-time mixing enables production in 0.25 m³ increments, tailored to immediate site demands, cutting leftover material by 89% versus batch-and-transport methods. Surge bins capture residual mix from cleaning cycles, and digital job calculators prevent overordering by aligning pour schedules with inventory levels.

Bridging the Gap: Advanced Tech and Operator Training Needs

While automation handles 92% of precision tasks, certified training remains vital for troubleshooting sensor calibration and interpreting diagnostics. Manufacturers now integrate augmented reality overlays into control panels, providing virtual guidance for verifying aggregate gradation and validating slump results against project specs.

Safety, Sustainability, and Environmental Advantages

Safer Operations in Confined or Urban Construction Zones

Self loading mixers that combine batching and transport functions all in one machine help cut down on traffic jams and equipment clutter in those cramped job sites we all know too well. These machines have smaller turning circles and come with automatic stabilizers which makes them much safer to operate. According to recent data from Construction Safety Alliance (2024), accident rates drop around 32% in city areas where space is at a premium. What's more, operators get access to full view cameras plus warning systems that beep when something gets too close. This combination really helps keep workers safe around foot traffic and delicate structures like historic buildings or newly laid pipes.

Lower Carbon Footprint via Reduced Transport Trips

Each avoided ready-mix truck round-trip saves approximately 250 kg of CO² annually. For a typical 100 m³ pour, this translates to 8.5 metric tons of CO² saved–equivalent to powering 2.3 homes for a year (2024 data from the World Green Building Council). These reductions support global decarbonization goals in construction.

Sustainable Practices Enabled by Just-in-Time Concrete Mixing

On-demand mixing prevents waste from premature curing–a $740 million annual issue industry-wide (Global Concrete Institute 2024). Precise batching cuts cement overuse by 12–15%, while closed-loop water recycling reduces freshwater consumption by 30%. These practices comply with ISO 14001 standards, as detailed in the 2024 Concrete Sustainability Report.

Improved Working Conditions and Operator Experience

Ergonomic cabins with vibration-dampened seating and noise levels below 25 dB reduce fatigue during extended shifts. Centralized controls allow single-person operation without exposure to dust or manual handling risks, decreasing OSHA-recordable incidents by 41% (Occupational Health Journal 2023). Real-time air quality monitoring further protects crews in enclosed environments like tunnels or basements.

Why Big Factory Manufacturing Builds Trust in Self-Loading Mixers

Advanced Engineering and Rigorous Quality Standards

Big manufacturers rely on ISO certified production setups where robots handle welding tasks and computer aided designs guide the process, achieving pretty much pinpoint accuracy down to around 0.1mm when making mixer drums. The hydraulic components get put through their paces with long lasting stress tests that run for three full days straight, while loading arms must pass durability checks involving over ten thousand cycles, which is actually 35 percent more rigorous than what most industries require. Looking at data from the latest Material Handling Report released in 2024 shows something interesting too. Factory made equipment tends to have about ninety eight percent fewer major parts failing compared to what comes out of smaller local workshops. Makes sense really since bigger operations can afford better quality control measures.

Innovations in Mobile Mixer Durability and Performance

Recent advancements include:

- Corrosion-resistant chromium-molybdenum alloy drums extending lifespan eightfold

- AI-powered load sensors preventing 92% of overload incidents

- Regenerative hydraulic systems reducing energy consumption by 27%

Comprehensive Support: Warranty, Service Networks, and Data Monitoring

Leading manufacturers offer:

- 5-year structural warranties (compared to the industry standard of 2 years)

- 48-hour parts delivery to 86% of global job sites

- Remote IoT diagnostics resolving 73% of issues before failure

Proven Reliability in Large-Scale Infrastructure Projects

Factory-built self-loading mixers have performed under extreme conditions, including:

- 18km tunnel projects in Alpine regions operating at -25°C

- Coastal megaprojects with over 500 daily mixing cycles

- Disaster recovery operations maintaining 98% uptime

This combination of engineering rigor and global support explains why 89% of heavy construction firms specify factory-built models for mission-critical work (2023 Global Construction Survey).

FAQ

What is a self-loading mixer truck?

A self-loading mixer truck is a mobile concrete mixer that integrates the functions of storing, batching, and mixing concrete within a single vehicle, eliminating the need for separate batching plants and reducing dependency on ready-mix suppliers.

What are the benefits of using self-loading mixer trucks on construction sites?

These trucks save time and costs by reducing equipment requirements and labor needs, offering real-time mix adjustments, and minimizing waste. They are especially beneficial in remote or urban sites with space constraints.

How do self-loading mixer trucks contribute to environmental sustainability?

By reducing transport trips, these trucks lower carbon emissions. They also enable just-in-time mixing to prevent waste, reduce cement use, and incorporate closed-loop water recycling, supporting sustainable construction practices.

Are self-loading mixer trucks safe to use in urban environments?

Yes, they are designed for safer operations with features like smaller turning circles, automatic stabilizers, full-view cameras, and proximity warning systems, mitigating accident risks in confined spaces.

What is the estimated return on investment for self-loading mixer trucks?

The initial investment, which ranges between $180,000 and $220,000, typically achieves payback within 3-5 years, providing long-term cost savings through reduced labor, waste, and maintenance requirements.

Table of Contents

- How Self-Loading Mixer Trucks Reduce Operational Dependencies

- Cost and Time Efficiency in Real-World Construction Applications

- Precision Automation and Consistent Concrete Quality Control

- Safety, Sustainability, and Environmental Advantages

- Why Big Factory Manufacturing Builds Trust in Self-Loading Mixers

-

FAQ

- What is a self-loading mixer truck?

- What are the benefits of using self-loading mixer trucks on construction sites?

- How do self-loading mixer trucks contribute to environmental sustainability?

- Are self-loading mixer trucks safe to use in urban environments?

- What is the estimated return on investment for self-loading mixer trucks?